Tank and Boom Options

With either a 1,600 gallon or 2,000 gallon tank, cover more acres in a day to maximize your return on investment.

We offer a variety of boom configurations to fit your operations, ranging from 90 ft.,100 ft.,120 ft.,and 132 ft. The stainless steel boom plumbing and recessed nozzle bodies within the boom structure for greater protection.

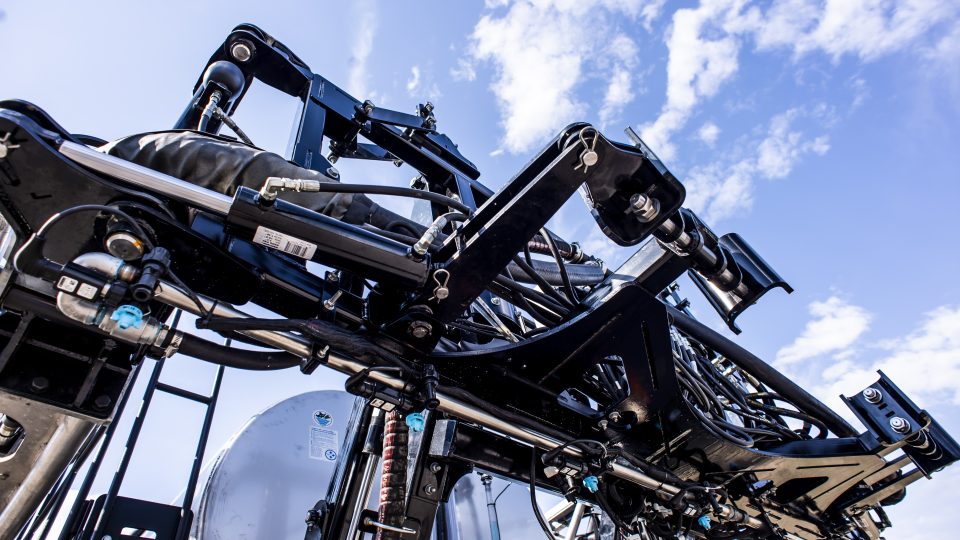

Heavy Duty Center Section

The newly designed self-leveling center rack is made to withstand the most severe field conditions while offering years of trouble free use. The yaw motion of the center section is controlled by multi-directional dampening cushions and shock system which are adjustable to fit the operator's preference. Fore and aft boom movement is minimized by the mechanical dampeners that dissipate the effects of cornering and sudden start/stopping, which decreases boom fatigue.

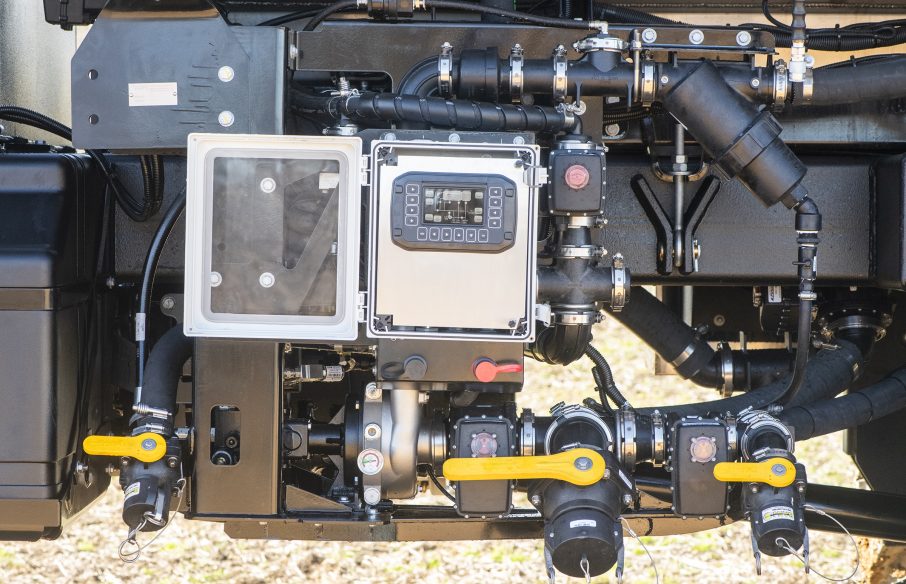

Loading Station

Our newly designed loading station has been engineered with operator ease and efficiency in mind. The load station has all electronic valves that are controlled through an intuitive touch display. Unlike a manual system, the display allows for one-touch operation to control the required valves to perform a specific function. The display also includes critical readouts such as machine RPM’s, Sparge setting and pressure, and tank volume. The load station also has a dedicated tank for tank cleaner to make the tank cleaning process easy and efficient.

Recirculation System

With a continuous boom circuit that leads back to the tank, you can prime the booms on the go to ensure that when you are ready to spray, you have full-rate product ready to come out of each spray tip without the need to do a wasteful pre-spray. With the boom priming system, there is an air cleanout that allows for compressed air to enter the boom circuit to blow any remaining product out the spray tips or back to the tank.

In-Line Plumbing

The stainless steel boom plumbing and nozzle bodies are recessed within the boom structure allowing for greater protection to the plumbing system for accidental strikes.

Vortex 390 Specifications

| Engine Make / Displacement | Cummins QSL 9 Liter Tier 4F with Compact Catalyst (CCC) and Selective Catalytic Reduction (SCR) | |||

|---|---|---|---|---|

| Horsepower @ 2000 RPM | 390HP (optional 430 HP) | |||

| Fuel / DEF Capacity | 150 gal / 30 gal | |||

| Transmission | Allison Automatic 3000 RDS with Dual Mode Shift Select & Shift-Lock / optional HydromechiVT | |||

| Transfer Case | Marmon Herrington 2-speed 2.5:1 ratio (5 speed low range / 4 speed high range) | |||

| 4 Wheel Drive | Selectable 2x4 - 4x4, Standard on all axle configurations | |||

| Axles - Standard Fixed Track | Meritor wheel end plantery, s-cam brakes, front & rear differential lock (36,000# front / 36,000# rear) | |||

| Axles - Optional Adjustable Width / 4-Wheel Steer | Dromos adjustable wheel track 114in to 144in (32,000# front / 32,000# rear) | |||

| Suspension | High Capacity Air-Ride Suspension with Heavy Duty Shocks, in-cab airbag dump, greaseless torque rods with extended-life polycarbonate bushings | |||

| Cab Controls | 7" Touch screen engine monitor with interactive diagnostics | |||

| Cab HVAC | Automatic dual zone HVAC system | |||

| Cab Radio | FM/AM Radio with Bluetooth and optional subwoofer | |||

| Cab Communication | Remote Chassis Telematics - Subscription Free | |||

| Cab Options | Heated and Ventilated Leather Seat, Leather Wrapped Steering wheel, High-Intensity LED Lighting, and Window Tint | |||

| Frame | 10" x 4" x 3/8" High Strength Tublar Steel with 40 mil Polyurea Coating | |||

| Overall Length | 292 in. (7.41 m) | |||

| Wheelbase | 168 in. (4.57 m) | |||

| Overall Width | 135 in. (3.4 m) | |||

| Overall Height | 153 in. (3.88 m) | |||

| Weight - Single Product | 31,250lbs (90’ booms) | |||

| Weight - Double Product | 31,250lbs (90’ booms) | |||

| Weight - Triple Product | 31,250lbs (90’ booms) | |||

| Row Crop Tires | 380/90R46 173D (Standard) | 380/105R50 179D (Optional) | 420/95R50 177D (Optional) | 480/80R50 177D (Optional) |

| Flotational Tires | 650/65R38 | 710/70R38 | 800/50R42 | |