Additional Options

Raven Visual Guidance System

Cab Options

RBR's cab was designed to keep the operator productive and comfortable during the longest of days. You can enhance your comfort with options below to make it the ultimate place to work.

- Factory tinted windows help keep the cab cool no matter how hot it gets.

- Heated/Vented Operators seat for year round comfort

- Leather Operators and training seat

- SiriusXM satellite radio

LED Lighting Package

High-intensity LED lighting increases visibility during low-light or night time application.

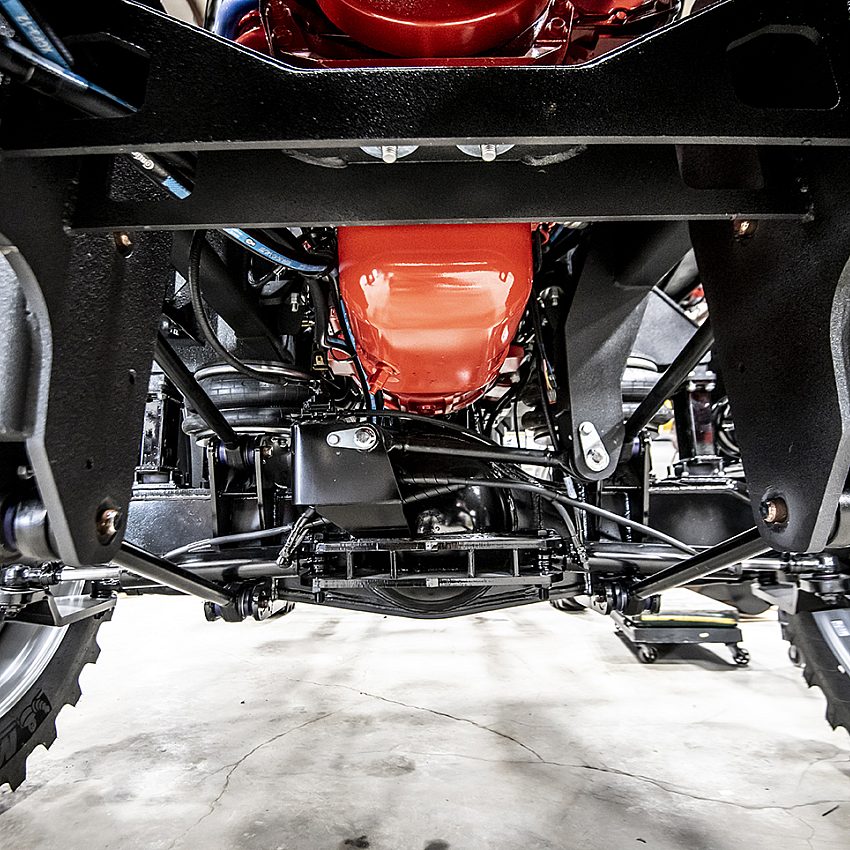

Crop Shield

When applying over-the-top, the front mounted shield helps prevent damage to middle and late season crops. The angled shield protects the crop from getting snagged on axles, air-lines, and other drive-line components.

Meritor Heavy Duty Planetary Axles

MERITOR® Heavy Duty Planetary Axles

- 36,000# front axle capacity / 36,000# rear axle capacity

- Driver controlled differential lock for the front and rear axle

- 16.5”x7” high-performance/heavy duty S-cam brake

- Utilizes Meritor 14X and 145 series axle carrier, for superior strength and dependability

Raven Field Computer and Guidance

With the RBR Viper 4+ field computer, effortlessly manage dry or liquid application with the touch of your finger. Pre-loaded with RBR chassis and attachment profiles, the Viper 4+ is a user friendly ISOBUS platform that is fully compatible with Raven steering and data transfer solutions.

Available on RBR units is Raven's new RS1 antenna. Offering precise steering guidance at both high and low speeds, with quick line acquisition to give you the ability to cover more acreage in a day. The simple design includes the guidance control module as well the slingshot modem for machine connectivity.

Narrow Track Axle

RBR's narrow track axles allow for a fixed 90" or 108" wheel track for easy maneuverability where roads or field access points restrict larger machines. The narrow track axles have been engineered with the same capacity and suspension of the standard machine.

Variable Track Axle System

RBR's (VTA) Variable Track Axle offers the convenience of an adjustable axle machine paired with the true strength and power RBR chassis are known for. Our VTA adjusts up to 30" simply by selecting a wheel track width from inside the cab through a touch screen display.

The VTA also includes 4-wheel steering (4WS). WIth 4WS engaged, the rear wheels follow the same path as the front when the machine is steered under 7MPH. This significantly reduces the overall turning radius allowing for increased maneuverability at the end of a pass. Also, the machine only creates one set of tracks in the field which minimizes damage to crops when compared to a 2-wheel steer machine.